Dreading the Thought of Endless Traffic?

BOWA’s Design Center eliminates selections process headaches

BOWA’s Design Center eliminates selections process headaches

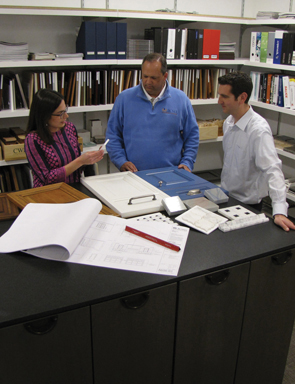

Understanding how frustrating and time consuming the materials selections process can be for clients who face countless showroom visits and endless traffic jams, BOWA’s Design Department recently introduced a new streamlined method for its design build projects. Based on feedback from clients who have already experienced this refreshing approach, the keys to its success are our approach to the selections process, our appropriately stocked Samples Library, our well-structured planning meetings and the seamless interaction amongst the BOWA team.

After moving into our new offices about one year ago, BOWA’s Design Department got to work on filling the shelves in our Samples Library with the most recommended and frequently requested samples of cabinets, tiles, countertops, paint and more. The goal was to provide enough options to be thorough, without being overwhelming. They then compiled a library of brochures, online resources, photo galleries and other tools to supplement the physical samples as needed.

With the resources in place, BOWA’s Lead Architect Bobby Han and his team then set out to develop an efficient method for encouraging thoughtful materials selections. Instead of clients running from showroom to showroom with a laundry list of items needed, those working on BOWA’s design build projects today enjoy a process that has been boiled down to a couple well-organized, intensive sessions in the Design Center. From the comfort of BOWA’s library, clients are able to review options, collaborate with the team, understand pricing and design impacts and make decisions on the spot. With a dozen or so clients having already moved through the new process, we’ve found that we can get 60-75% of decisions made in the first few hours, with the balance completed in just one or two more focused meetings. A vast improvement for and great relief to our clients!

With the resources in place, BOWA’s Lead Architect Bobby Han and his team then set out to develop an efficient method for encouraging thoughtful materials selections. Instead of clients running from showroom to showroom with a laundry list of items needed, those working on BOWA’s design build projects today enjoy a process that has been boiled down to a couple well-organized, intensive sessions in the Design Center. From the comfort of BOWA’s library, clients are able to review options, collaborate with the team, understand pricing and design impacts and make decisions on the spot. With a dozen or so clients having already moved through the new process, we’ve found that we can get 60-75% of decisions made in the first few hours, with the balance completed in just one or two more focused meetings. A vast improvement for and great relief to our clients!

While less hassle and time required are the obvious client benefits, there are countless others. For example, our team can help to ensure that materials are within the client’s approved budget range. We hate to see when items chosen independently cost more than  expected, leading to challenging conversations, disappointment or rework. Additionally, an early focus on selections helps to ensure that long-lead items are ordered in a timely manner and available onsite when needed. Lastly, an aggressive focus on finalizing all materials during the schematic design phase helps to ensure that budgets can be locked in and the project fully prepared for production, avoiding schedule delays and potentially costly change orders down the road.

expected, leading to challenging conversations, disappointment or rework. Additionally, an early focus on selections helps to ensure that long-lead items are ordered in a timely manner and available onsite when needed. Lastly, an aggressive focus on finalizing all materials during the schematic design phase helps to ensure that budgets can be locked in and the project fully prepared for production, avoiding schedule delays and potentially costly change orders down the road.

When clients, who once challenged us because they thought we were pushing too hard for selections, later thank us because they are able to sit back and watch their projects unfold and all the pieces fall in place seamlessly, we know we got the process right!

OTHER POSTS